An umbrella is a common everyday item that we have and is the best solution for rainy days and the sun.

However, have you ever wondered about the manufacturing process of an umbrella?

In this article, we will explore the intricate process of creating a durable and high-quality umbrella, from the selection of materials to the hand-assembly process.

Selection of Fabrics

The first step in the umbrella manufacturing process is the selection of fabric. There are different umbrella fabric types present. The quality of the umbrella material used determines the durability and performance of the umbrella.

The canopy of the umbrella is typically made of nylon or polyester, which is lightweight and waterproof. Golf umbrella canopies are often larger and made of thicker fabric to withstand windy conditions.

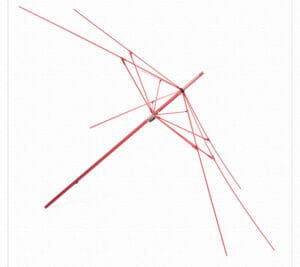

Ribs and Stretchers

The ribs and stretchers are the frameworks of the umbrella that supports the canopy. The ribs are the thin, flexible rods that run along the canopy, and the stretchers are the rods that connect the ribs to the shaft of the umbrella. These components are usually made of lightweight materials such as aluminum or fiberglass.

The shaft of the Umbrella

The shaft of the umbrella is the long, central part of the umbrella that connects the handle to the canopy. It is usually made of wood or metal and is designed to be both lightweight and durable. The shaft of each umbrella is carefully crafted to ensure that it is straight and stable.

Canopy of the Umbrella

The canopy of the umbrella is part of the umbrella that provides protection from the rain or the sun. It is usually made of nylon or polyester and is available in a variety of colors and designs. The canopy of umbrella is hand-sewn to the ribs and stretchers to ensure that it is securely attached.

Top of the Umbrella

The top of the umbrella is part of the canopy that is visible when the umbrella is closed. It is typically made of plastic or metal and is designed to be both durable and aesthetically pleasing. The top of the umbrella is often customized with logos or designs for promotional or advertising purposes.

Umbrella Frame

The umbrella frame is the combination of the ribs, stretchers, and shafts of the umbrella. It is designed to be both lightweight and sturdy, and it provides the structure for the canopy to be attached. The frame of the umbrella is carefully crafted to ensure that it is strong enough to withstand windy conditions.

Making an Umbrella

The process of making an umbrella is a combination of machine and handcrafting techniques. The canopy of the umbrella is slid onto the ribs and stretchers using a machine, while the shaft and handle are handcrafted. The ribs and stretchers are inserted into the shaft of the umbrella, and the canopy is hand-sewn to ensure that it is securely attached.

Hand-Assembly Process

The hand-assembly process is an essential part of the umbrella manufacturing process. Each part of the umbrella is carefully crafted and assembled by hand to ensure that the final product is of high quality. The handle is attached to the shaft of the umbrella, and the canopy is hand-sewn to the ribs and stretchers to ensure that it is securely attached.

Quality of the Umbrella

The quality of the umbrella is an essential aspect of the manufacturing process. A high-quality umbrella should be durable, waterproof, and resistant to windy conditions. The handle should be comfortable to grip, and the umbrella should be easy to open and close. Quality checks are conducted at various stages of the production process to ensure that each umbrella meets the required standards.

Collapsible Umbrella

A collapsible umbrella is a type of umbrella that can be folded and stored in a compact size. It is designed for easy transportation and storage. The frame of a collapsible umbrella is typically made of lightweight materials such as aluminum or fiberglass, and the canopy is made of nylon or polyester. Collapsible rain umbrellas are popular among commuters and travelers because of their convenience and portability.

Production of Umbrellas

The production of umbrellas involves a complex process that requires attention to detail and precision. The manufacturing process begins with the selection of materials and continues with the crafting of each part of the umbrella. Each part is carefully assembled by hand to create a high-quality umbrella that is both durable and functional.

Custom Umbrellas

Custom umbrellas are a popular promotional item for businesses and organizations. They can be customized with logos, slogans, and designs to create a unique and memorable product. Custom umbrellas are typically made to order, and the manufacturing process involves specialized techniques to ensure that the design is accurately replicated on the canopy of the umbrella.

Classic Umbrella

The classic umbrella is a timeless design that has been in use for centuries. It is a simple and functional design that provides protection from the rain or the sun. Classic umbrellas are typically made of high-quality materials and are designed to be both durable and aesthetically pleasing.

Conclusion

The umbrella manufacturing process is a combination of machine and handcrafting techniques that requires attention to detail and precision. From the selection of materials to the hand-assembly process, each part of the umbrella is carefully crafted to create a durable and high-quality product. Whether it is a collapsible rain umbrella or a classic umbrella, each umbrella is designed to provide protection from the elements while being easy to use and aesthetically pleasing. The quality of the umbrella is an essential aspect of the manufacturing process, and quality checks are conducted at various stages to ensure that each umbrella meets the required standards.