Umbrellas are necessary for rainy weather, but choosing the right type of umbrella can make all the difference. Regarding umbrella types, the two most popular options are bubble umbrellas and regular umbrellas. In this article, we will take a closer look at bubble umbrellas vs regular umbrellas and help you decide which one is right for you.

Umbrellas are a common sight on rainy days. These protects individuals from rain and other harsh weather conditions. However, have you ever wondered how umbrellas are made? In this article, we will discuss the manufacturing process of umbrellas, the various parts that make up an umbrella, and the materials used to create this essential rainy day.

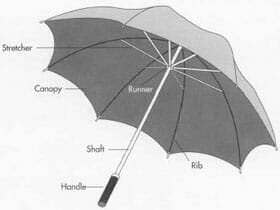

The Parts of an Umbrella

An umbrella has several parts, including the canopy, the rib, the stretcher, and the shaft. Each part plays a vital role in the umbrella’s structure and function.

Canopy: The canopy is the top part of the umbrella that provides coverage from the rain. It is typically made of waterproof materials like nylon, polyester, or PVC.

Rib: The rib is the umbrella part supporting the canopy. There are typically between six and eight ribs on a standard umbrella. The rib is typically made of metal or fiberglass.

Stretcher: The stretcher is the umbrella part that connects the rib to the shaft. It is also typically made of metal or fiberglass.

Shaft: The shaft is the long handle of the umbrella. It is typically made of wood, metal, or plastic.

The Manufacturing Process of Umbrellas

The manufacturing process of umbrellas involves several steps. These steps are as follows:

-

Cutting the Material: The first step in creating an umbrella is cutting the canopy material into the appropriate shape and size. The canopy is typically made of nylon and cut into triangular shapes.

-

Sewing the Canopy: After the material is cut, the triangular shapes are sewn together to create the canopy. The seams are reinforced to ensure that the umbrella is durable.

-

Attaching the Ribs and Stretchers: Once the canopy is complete, the ribs and stretchers are attached. The ribs and stretchers are typically made of fiberglass or metal and are attached to the canopy using a combination of stitching and metal fasteners.

-

Creating the Shaft: The umbrella shaft is created separately from the canopy. It is typically made of wood, metal, or plastic. The shaft is shaped and smoothed using a lathe.

-

Attaching the Shaft: After the shaft is complete, it is attached to the umbrella frame using a metal ferrule. The ferrule is typically made of brass or aluminum.

-

Adding the Handle: The final step in creating an umbrella is adding the handle. The handle is typically made of wood, metal, or plastic. It is attached to the shaft using a screw or a rivet.

Modern Umbrellas

Today, there are many different types of umbrellas available on the market. Modern umbrellas are typically made of nylon or polyester fabric and often have automatic open and close features. These umbrellas have metal frames that are lightweight and easy to carry.

Ribs and Stretchers

The ribs and stretchers are an essential part of the umbrella’s structure. The ribs are the metal or fiberglass supports extending from the umbrella’s center to the outer edges. The stretchers are the metal or fiberglass pieces that connect the ribs to the shaft. These parts work together to create a sturdy, durable umbrella that withstands strong winds and heavy rain.

Fiberglass

material used in modern umbrellas. Fiberglass is strong, lightweight, and durable, making it an ideal choice for umbrella ribs and stretchers. Fiberglass is also flexible, so it can bend and flex without breaking. This makes fiberglass umbrellas more resistant to wind damage than those made from other materials.

How an Umbrella is Made

In conclusion, umbrellas are an essential item for many people during rainy weather, and the manufacturing process requires precision and attention to detail. The combination of materials, including nylon, fiberglass, metal, and wood, all create a sturdy and durable umbrella.

Modern umbrella technology advancements, such as automatic open and close features, have made them more convenient and user-friendly. The use of fiberglass in the rib and stretcher construction has also improved the durability of modern umbrellas.

Whether walking in the rain, enjoying a day at the beach, or simply needing shade on a sunny day, umbrellas are a valuable and practical item. Creating an umbrella may seem simple, but manufacturing requires skill and expertise to create a high-quality and functional product. So, next time you pick up an umbrella, take a moment to appreciate the craftsmanship and precision that went into its creation.